Acoustic Louvers: Noise Reduction and Workers’ Health in Industrial Settings

The demand for architectural and mechanical screen fencing equipment is on the rise, with an influx of progressive cities requiring property owners to install visual barriers around HVACs, transformers, generators, and similar fixtures. Local codes require these items to be obscured from public view, and failure to accommodate may result in costly fines. For these reasons, PalmSHIELD, the nation’s leading screening contractor, offers a broad variety of screens—available in multiple styles and colors, and custom-built to your job site’s parameters.

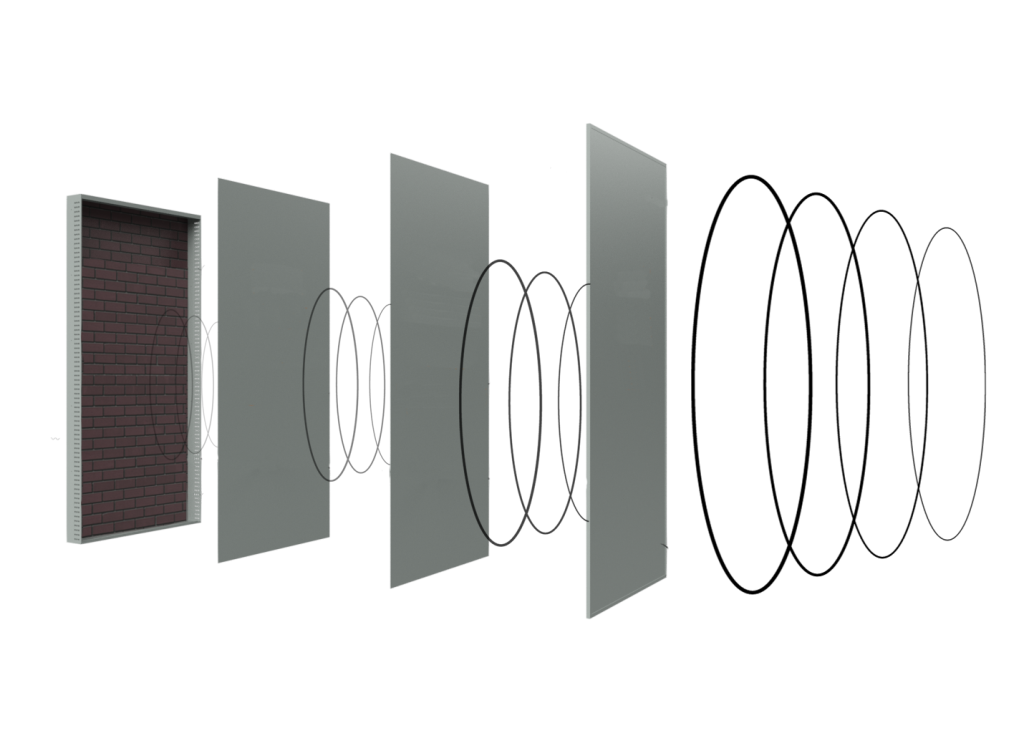

In some cases, though, it’s important to take a step beyond obscuring unsightly objects from view. If you manage an industrial park or related setting, you know—all too well—of the incessant mechanical noise during the work day. Even if your equipment remains hidden behind a professionally fabricated barrier, the clanging sounds remain prevalent. Prolonged exposure to such noise can be distracting and even damaging to workers’ health. Recognizing this, PalmSHIELD’s designers sprung into action, and the result of their labors was our Silere acoustic screening system. When it comes to sound absorption panels for industrial settings, there is no better choice.

Contact PalmSHIELD today for a free quote on acoustic screening!

Why is sound absorption important for industrial settings?

Of course, noise at industrial venues will always be present to a degree. There’s so much activity—from machines to forklifts—so how does sound absorption benefit employees? It’s first important to consider the long-term impact unimpeded noise can cause. According to the Occupational Safety and Health Administration, exposure to noise levels at or exceeding 85 decibels can result in hearing loss. As they also note, “the louder the sound, the shorter the amount of time” it takes to cause internal ear damage. Here’s a statistical fact: the National Library of Medicine reported in a study that twenty-two million U.S. workers “reported exposure to hazardous workplace noise.” Trades where this was present include: mining; lumber/wood product manufacturing; motor vehicle operations; and construction.

Exposure to such conditions is never safe, and it can be especially dangerous to personnel who’ve made this their full-time living. If precautions are never taken, long-term impact on employees’ health can include increased stress, fatigue, and stemming health issues such as high blood pressure. All this also impacts their ability to remain a productive member of the team—thereby negatively impacting your business.

At the same time, you can’t shut down essential equipment. For that reason, it is imperative to soften hazardous noise levels—and our Silere acoustic screening is a great way to achieve this.

How does PalmSHIELD’s Silere Acoustic Screening Benefit You?

The panels of these screens are composed of Silk Metal micro-perforated aluminum, a material designed to limit sound reflections and greatly reduce echo. In acoustics, there is something called a Noise Reduction Coefficient (or NRC for short). This coefficient is measured on a scale of zero to one—zero meaning no sound reduction and one meaning total sound absorption. The Silere panels boast an NRC of 0.80—meaning they greatly reduce the noise of the equipment they enclose. Installing our panels around equipment—whether ground-based or situated on a rooftop—can go a long way in increasing your team’s comfort in the work environment.

What are my design option on Silere Acoustic Screens?

PalmSHIELD’s sound-reducing acoustic screens are available in three distinct styles:

- Acoustic Solid Panel. Incorporating any of PalmSHIELD’s solid panel infill with a state-of-the-art mass-loaded vinyl noise barrier and Acoustic Surfaces Silk metal box design to allow airflow for maximum noise reduction. The Noise S.T.O.P. Mass Loaded Vinyl Sound Barrier is a high-density exterior-rated barrier. The silk metal micro-perforated metal is offset from the solid architectural panel and vented at the bottom to allow airflow and maximize the silk metal’s performance.

- Full Air Foil Acoustic Louvered Panel. These louvered panels incorporate a 3” x 1” noise-dampening foam-filled foil louver, allowing for a 50% openness. The back of the louvered panel is 100% covered with the perforated Acoustic Surfaces silk metal material with an approximate 10% openness. These louvered panels provide some degree of air movement with maximum noise reduction in the foam foam-filled louvers and state-of-the-art noise-reducing silk metal materials.

- Semi Air Foil Acoustic Louvered Panel. These louvered panels incorporate the 3” x 1” noise-dampening foam-filled foil louvers that allow for an adjustable openness. When airflow is critical, these acoustic panels incorporate a varying degree of coverage with the silk metal perforated material. This design leaves a specified amount of the foil louvers uncovered at the top or bottom of the screened panel.

Like all of our mechanical screen fencing equipment products, the Silere panels are custom-designed and built according to your job site’s specific needs. Contact our sales team today for a free estimate on your project!

Contact PalmSHIELD today for a free quote on acoustic screening!