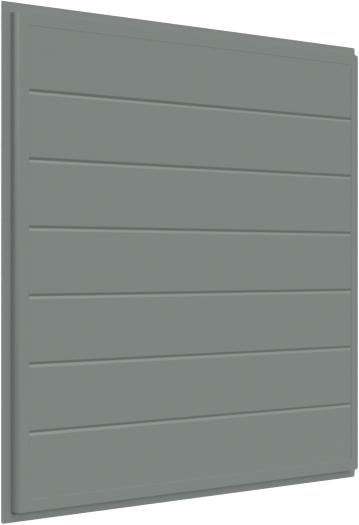

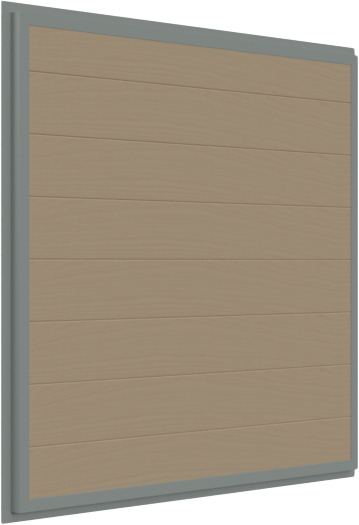

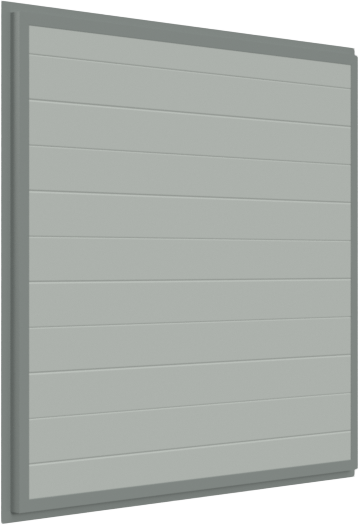

Built Tough, Designed Beautifully

Whether you’re looking for an affordable, easy-to-install option or a versatile design that complements your building’s architecture, Forte delivers:

- Withstands wind speeds of up to 150 mph.

- Utilizes industry-standard panel sizes to keep costs low.

- Minimal parts and a streamlined installation process.

- Options for diagonal column or cantilevered mounting.

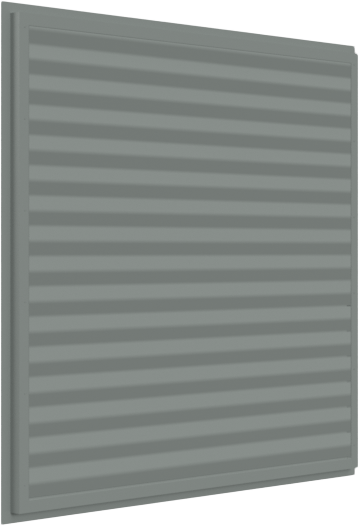

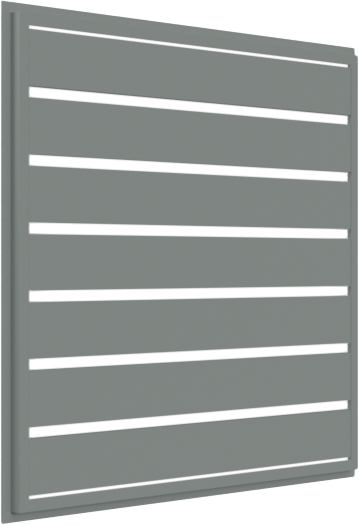

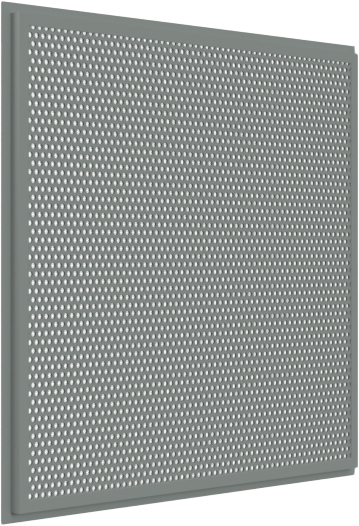

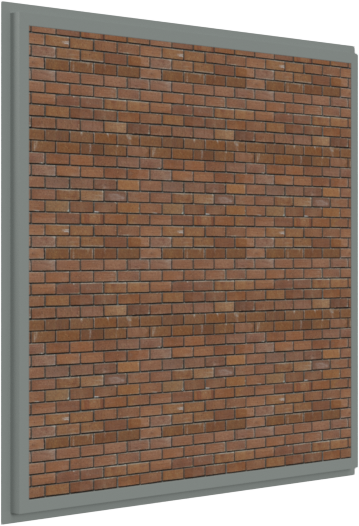

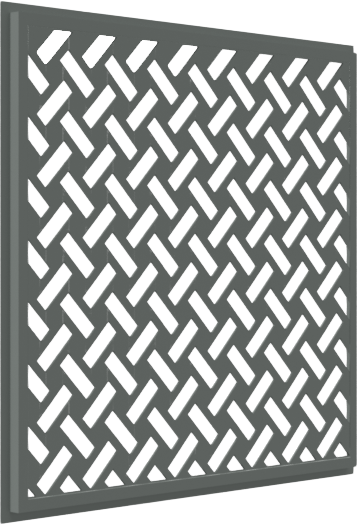

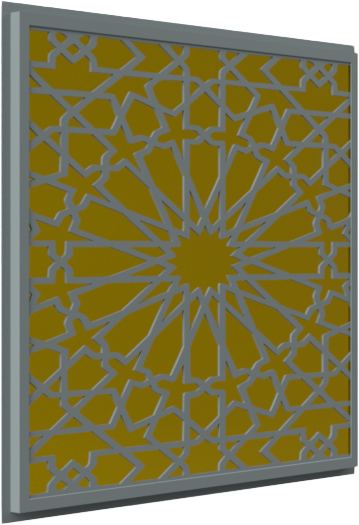

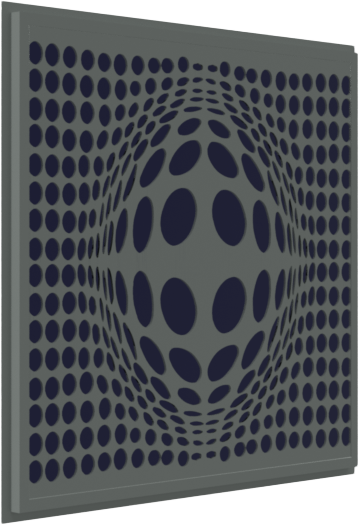

- A variety of designs to match your building’s exterior.

- Professional service available across the country.

- Tailored solutions to meet unique project requirements.