Cable railing is growing in popularity due to its slim and discreet appearance that leaves the eye to look beyond the railing. The challenge is cable railing must meet standard IBC / UBC codes, requiring practically no deflection. To meet this requirement the cables must be tensioned to some incredible levels, creating a considerable amount of pull on both ends of termination.

PalmSHIELD has been fabricating cable railing for almost twenty years. We know a thing or two about cable railing. Specifically, many installations fail over time to maintain proper tension. Imagine eleven cables, each tensioned to several hundreds of pounds of pull, pulling on one two inch square post screwed down to the top of a soft cedar deck board or stair plank. System failure! To prevent this mishap, PalmSHIELD uses their unique and proven fully framed panel design. With fully framed panels, the tension is transferred to the frame and not to your deck or stairs.

PalmSHIELD cable systems are designed to be accompanied with code compliant stair grab rails. All of our sections are custom fabricated. PalmSHIELD uses a rigid, thin cable stabilizer bar in the panels to support the long cable runs. At changes in slope, a stabilizer bar will support the cables without the use of additional posts. Fewer posts leaves more to be desired as you look beyond the cable rail system.

PalmSHIELD offers three unique cable designs. Each one has its own unique application.

- ATTILA – Our exclusive fully framed design utilizing a single cable strewn back and forth

- ELLAC – PalmSHIELD’s one-of-a-kind adaptable design for changing terrains and radius

- RUGA – the traditional cable railing design with PalmSHIELD framework

Features & Benefits

- Cable rail designs unique to your application

- Both custom fabricated to meet your site specific conditions or field adjustable

- 20 years of cable rail design to assure all standard IBC & UBC codes are met.

- Fully fabricated systems that require only a minimal amount of installation. No worries over cable installs.

Popular Applications

- Patios

- Courtyards

- Walkways

- Stairs

- Ramps

- Upper Decks

- Crowd Control

Railing Infill Options

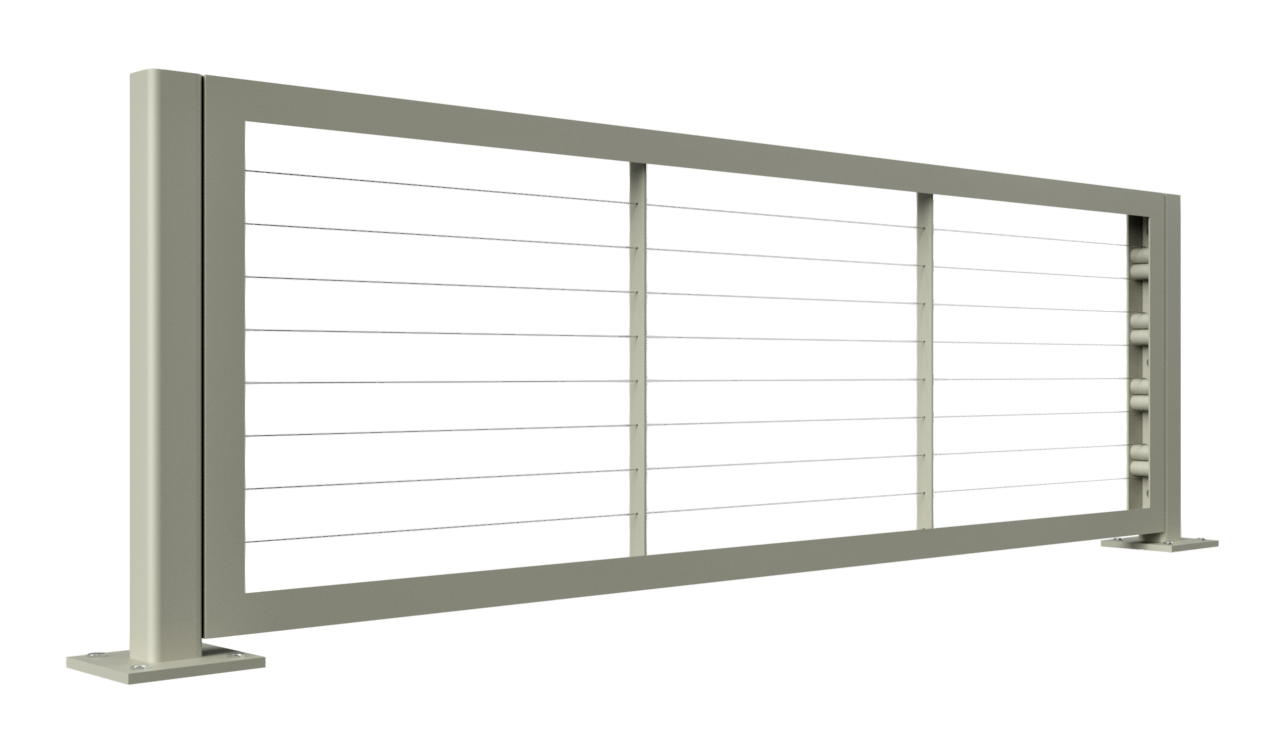

Attila Cable railing

Material: Aluminum framework. Stainless steel cable and hardware.

Cable Thickness: 1/8” to 3/16”

Height: Typical 36” – 42”

Width: Individual panels may be 20’ in length.

ATTILA utilizes a single cable design where the cable is attached at the top of the panel and then strewn back and forth over a series of spools to a final and single tensioner at the bottom. This is a cleaner and more interesting design than traditional cable railing. It has a real architectural look for those installations that require more than a simple cable railing. Each cabled panel comes complete with fully installed cables. The panels and posts are predrilled, making installation simple and flawless. A traditional deck railing has at least four to five independent field installed cable runs that may result in system failure if the posts anchoring fails. This installation would take several days between anchoring posts and installing almost one hundred tensioners. With the PalmSHIELD system, a traditional deck railing will take a fraction of the time and no worries over failed post connections.

Panel Infill Options

ellac cable railing

Material: Galvanized steel posts and rails. Stainless steel cable and hardware.

Cable Thickness: 1/8” to 3/16”

Height: Typical 36” – 42”

Width: Posts o.c. 10’ with middle support.

ELLAC is our hinged, field adjustable cable railing system. It utilizes a mechanical hinge connection at the top and bottom rail that allows the railing to field adjusted to changes in elevation and slope. In-between each rail centered between the post is a hinged slim steel profile that keeps the cables aligned and assures the cables will meet code compliance yet very discreet. This one-of-a-kind installation is perfect for large installations that may have varied slopes and radius.

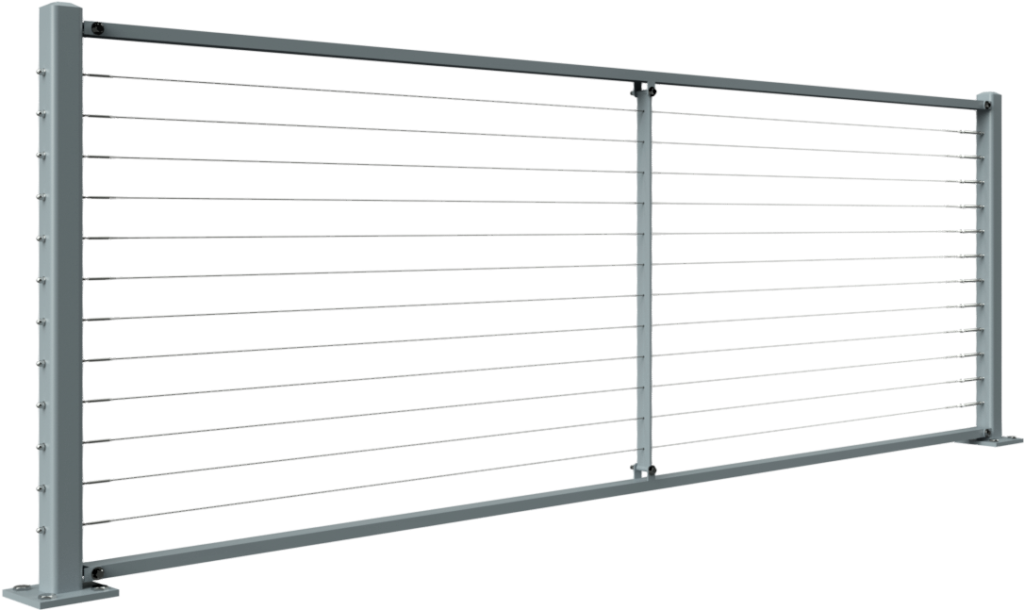

Ruga cable railing

Ruga cable railing

Material: Aluminum framework 2” square posts and rails. Stainless steel cable and hardware.

Cable Thickness: 1/8” to 3/16”

Height: Typical 36” – 42”

Width: Sections shop fabricated in largest possible.

RUGA, our traditional railing system is designed with square tubular posts and rails. A bottom rail is incorporated to assure post tension does not result in post failure. Posts on center may vary when thinner vertical rail supports are added to assure cable support every 5’ o.c. Panels are shop fabricated to the largest possible sections. Cable are field installed. RUGA systems are your traditional railing design based on PalmSHIELD’s years of experience.

Machiavelli Grating

PalmSHIELD is excited about our aluminum and steel bar grating railing and fence panel systems. Bar grating is popular as a vertical infill material due to its real three dimensional appearance. With bars varying from 1” to 1 1/2” wide, it provides a great deal of depth. Bar Grating consists of a series of bearing bars that intersect with cross bars to form a load-bearing panel. Panels are manufactured by welding, locked by swaging, or press-locked processes. A typical panel configuration has bearing bars spaced 1-3/ 16 inches on center with cross bars spaced 4 inches apart .Bar Grating is available in a wide selection of panel sizes; bar sizes and spacings; bar shapes; and material types.

This bar grating material is an excellent infill for being code compliant. PalmSHIELD provides several CAD and PDF drawings for you to reference. With this information, engineers and architects will have an easier time providing a complete set of specifications for bar grating panel systems. PalmSHIELD has been successfully manufacturing aluminum and steel bar grating railing products for over 25 years.

MACHIAVELLI GRATING

Material: Stainless, galvanized steel

Cable Bearings: 1″ – 1-1/2″ wide x 1-3/16″ spacing

Height: 36″ – 42″

Width: Full panel widths up to 20′

MACHIAVELLI bar grating consists of a series of bearing bars welded or pressed at various intervals to perpendicular cross bars to form a load-bearing panel. Panels are manufactured by welding, locked by swaging, or press-locked processes. A typical panel configuration has bearing bars that are spaced 1-3/16” inches on center with perpendicular cross bars spaced 4 inches apart (center to center).